Dongguang Xinglong Packaging Machinery Co., Ltd.

.HEBEI DONGGUANG XINGLONG PACKING MACHINERY CO., LTD. is a

well-known enterprise engaged in the professional production of

various kinds of carton machines. Over the past two decades, we

have introduced advanced technology at home and abroad and have

developed a series of products. Our products are popular with

customers.Our products are complete in specification and model, and

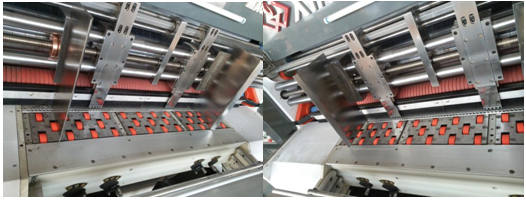

can meet the needs of different users. Our main products are

corrugated board production lines, ordinary printing presses,

high-speed printing presses, single facers, thin blade machines,

and rotary die-cutting machines. In the spirit of "excellence and

continuous pursuit of perfection", on the basis of "ensuring

quality and service", we pay more attention to corporate reputation

and always adhere to the "reputation first" principle. Our factory

implements a comprehensive quality management system. Our elegant

appearance, meticulous process, reasonable price and perfect

after-sales service have won praises among many business clients

worldwide.We have the development and design ability and a perfect

quality assurance system, perfect technology, complete mechanical

equipment, highly specialized talents, strong technical strength,

advanced inspection methods, and a complete management system. We

are responsible for the revitalization of Chinese carton machinery

to cooperate wholeheartedly with the vast numbers of users. We will

constantly improve product quality and after-sales service to meet

the needs of users.